Frequently asked questions

Here is a basic list of issues to be specified:

- Types of doors: interior or exterior?

- Models and finishes

- Door sizes or rough opening sizes to calculate the door sizes

- Number of doors

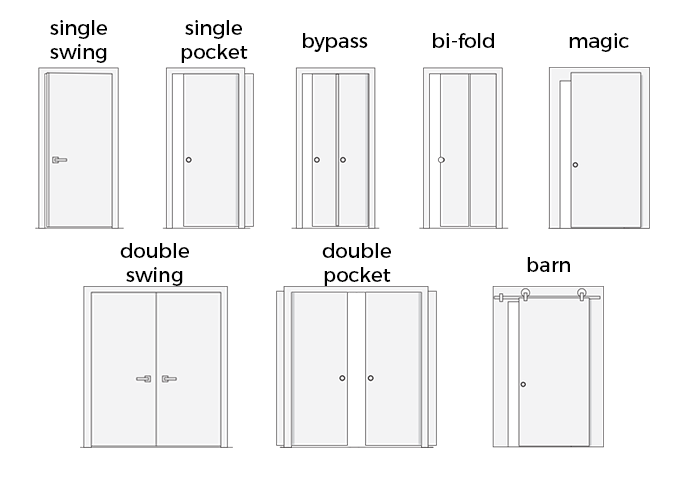

- Configurations (swing, bypass, pocket etc.)

- Types of hardware needed (handles? concealed or plain bearing hinges? tracks?)

- Swing directions (LHI - left hand inswing? RHI - right hand inswing?)

- Lockset functions (passage, privacy or keyed?)

- Additional options: automatic door bottom, frameless system etc.

- Project lead time (when are the doors needed at the job site?)

- Budget

- Any special requirements (fire ratings, etc.)

Orders will be accepted by:

- phone (848) 456-7050

- e-mail [email protected]

- through our web-site

Online order

- Choose a door and configure it according to your needs

- Add to cart

- If you need to order more than one door you can continue shopping and add more products to you cart

- Proceed to safe and secure checkout

- We shall notify you as soon as we receive your order

Order By E-mail

- Please contact our sales department at [email protected]

Order by Phone or Fax

- Call us at our toll free numbers (848) 456-7050

Order through our Sales Representative

For single and double door configurations

Subtract 2" from the height. This will determine the door slab size.

1

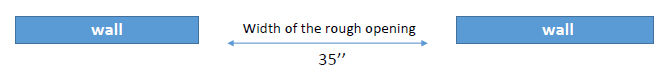

Let's imagine that we have measured the width of the rough opening and it equals 35"

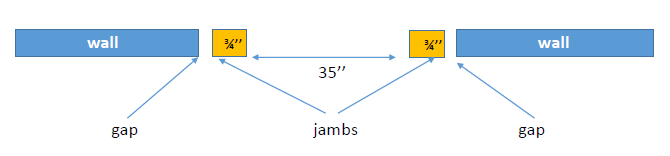

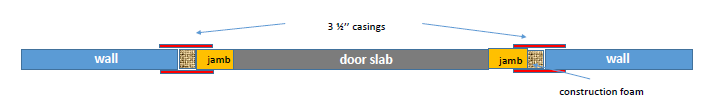

In order to determine the width of the door slab, we first of all need to subtract 2" from the width of the opening. So where do these 2 inches actually come from?

2

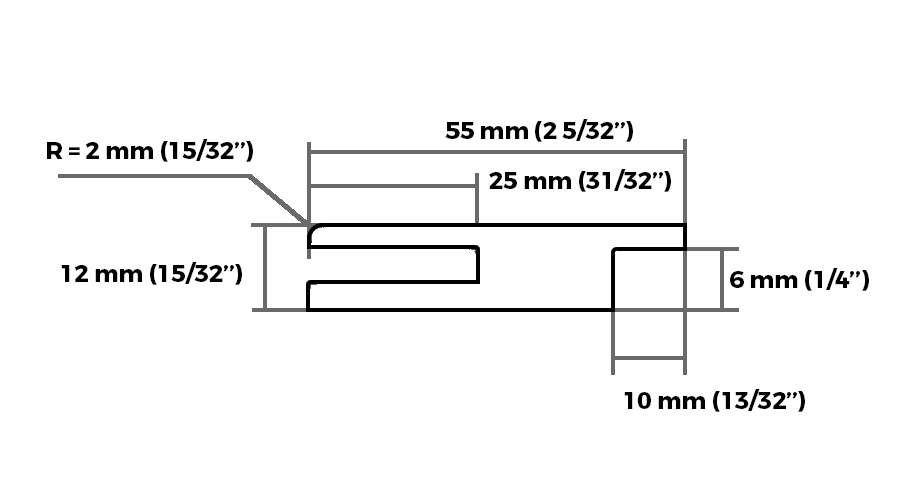

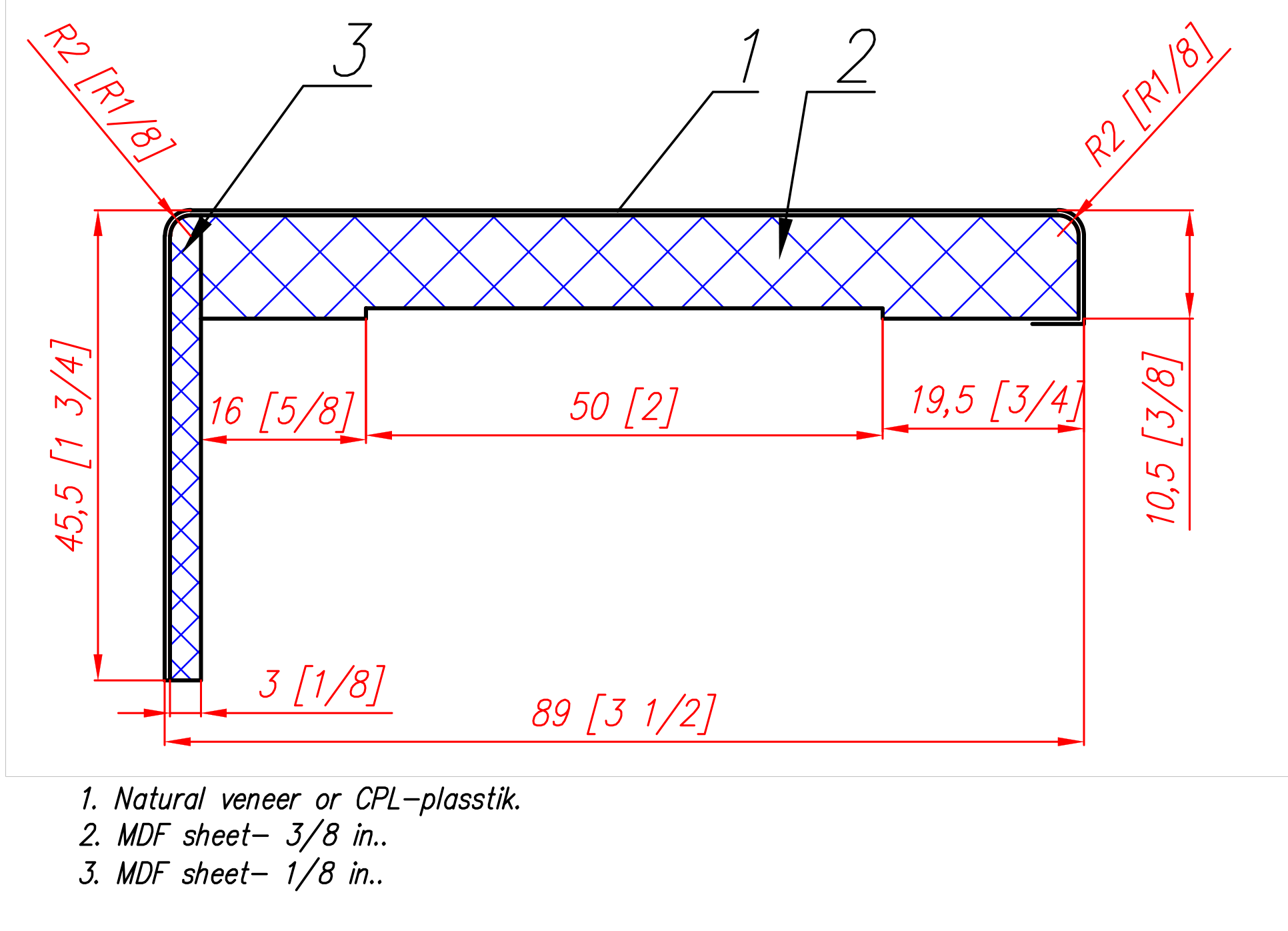

The standard thickness of

Doordesignlab jamb is 3/4".

3/4" + 3/4" = 1 1/2" is the total thickness of 2 jambs.

And we

leave the rest of the space (1/2") as technological gaps to be filled in construction foam.

So

this forms the 2 inches' width that needs to be subtracted from the overall width of the opening.

3

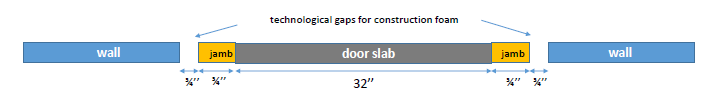

35" - 2" = 33"

Now we need

to determine which standard width is suitable for the 33" wide opening.

This is obviously

32".

And the remaining space will be filled width construction foam and covered with prefinished

casings.

4

Standard width of Door Design Lab casings is 3 1/2"

For barn, magic, bi-fold, bypass and pocket door systems

Please refer to the manuals provided by the hardware manufacturers.

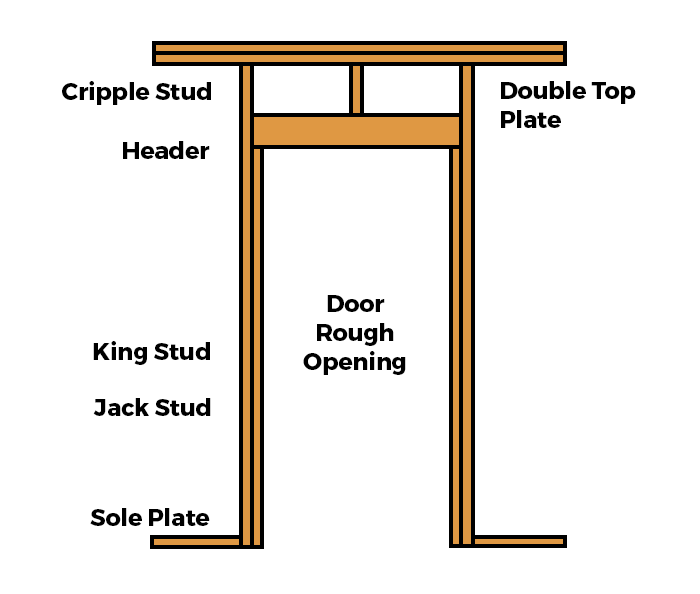

A standard US rough opening consists of:

One of the fundamental

elements here is a wall stud.

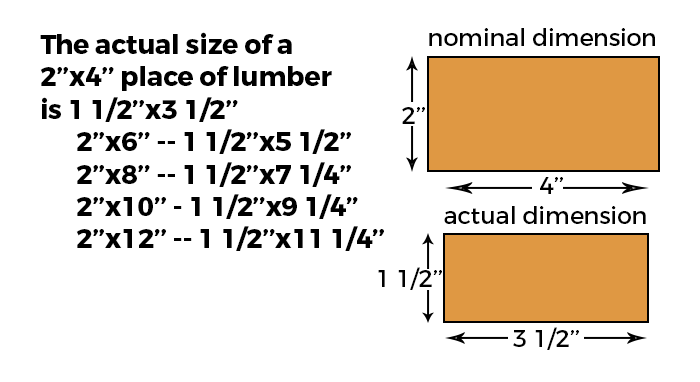

Studs are traditionally made of wood, usually 2"×4"

or 2"×6" dimensional lumber and typically placed 16 inches (406 mm) from each other's

center, but sometimes also at 12 inches (305 mm) or 24 inches (610 mm). The wood needs to be

dry when used otherwise problems may occur as the studs shrink and twist when they dry out.

Considering this fact, the actual sizes of the framing studs are:

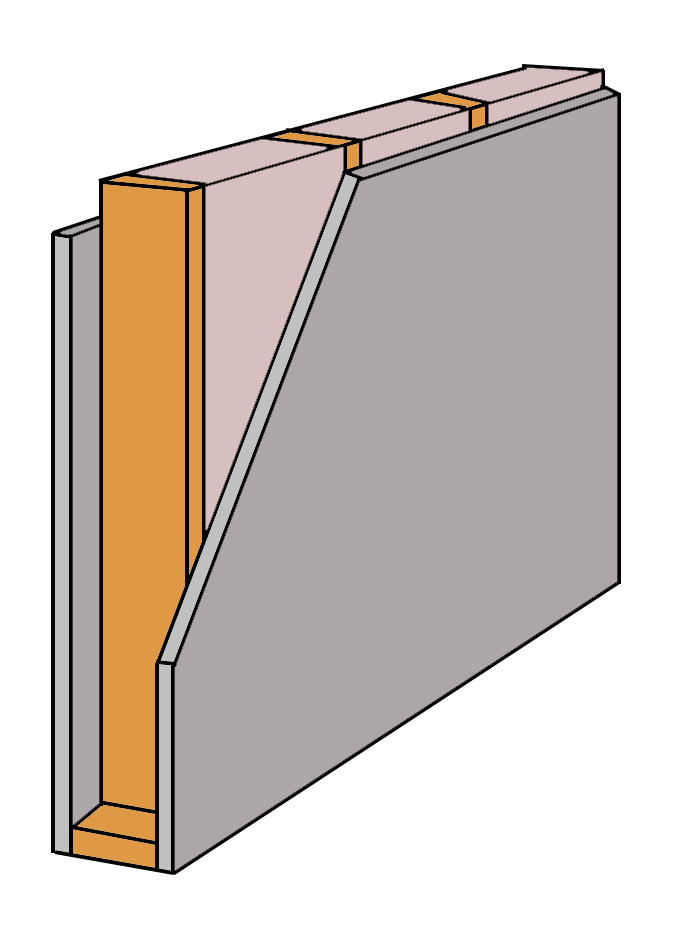

The standard 2"×4" or 2"×6" wall assembly is as follows:

Studs with insulation filling in between and a layer of drywall from both sides of the construction.The drywall is normally 5/8’’ thick. Sometimes several layers of drywall are used.This knowledge is important whenever you want to measure the thickness of the wall because it actually defines whether you need an extension or not.

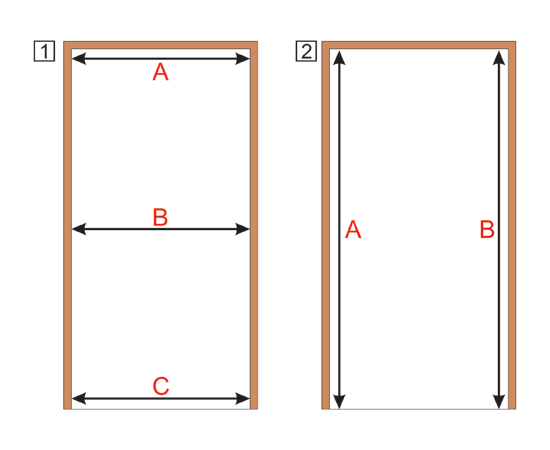

See the picture below in order

to learn how to accurately measure the size of the rough opening.

First, measure the width

between the studs of the doorway three times (picture 1) and record the smallest of the three

measurements.

Second, measure the height on both sides (picture 2) and record the smallest

measurement. Congratulations! You have determined the width and the height of the rough opening.

A door schedule is a tabulation, usually on a blueprint or in specifications, which list all doors required for a job, indicating sizes, types, locations, and special requirements.

| MARK | FUNCTION | WIDTH | HEIGHT | HARDWARE | DOOR MATERIAL | DOOR FINISH | FRAME | REMARKS |

|---|---|---|---|---|---|---|---|---|

| 1 | ENTRY DOOR | 66' | 9' - 2' | PUSH/PULL BAR W/ KEYED DEADBOLT |

ALUM. / GLASS | FROSTED CLASS / ALUM. FRAME |

ALUM, STOREFRONT |

BY STOREFRONT MFR.; PIVOT DOOR WITH OFFSET PIVOT |

| 2 | INTERIOR | 36' | 7' - 0' | PRIVACY | S.C. WOOD | STAIN / SEAL | WOOD | |

| 3 | INTERIOR | 36' | 7' - 0' | PRIVACY | S.C.WOOD | STAIN / SEAL | WOOD | |

| 4 | INTERIOR | 24' | 7' - 0' | PASSAGE | S.C.WOOD | STAIN / SEAL | WOOD |

A door schedule is the basis for providing a detailed and accurate quote to a customer and usually contains the following information:

- Door types and functions

- Door locations

- Door materials and finishes

- Door sizes

- Number of doors

- Configurations (swing, bypass, pocket etc.)

- Types of hardware needed (handles? concealed or plain bearing hinges? tracks?)

- Swing directions

- Lockset functions (passage, privacy or keyed)

- Fire ratings

- Other requirements

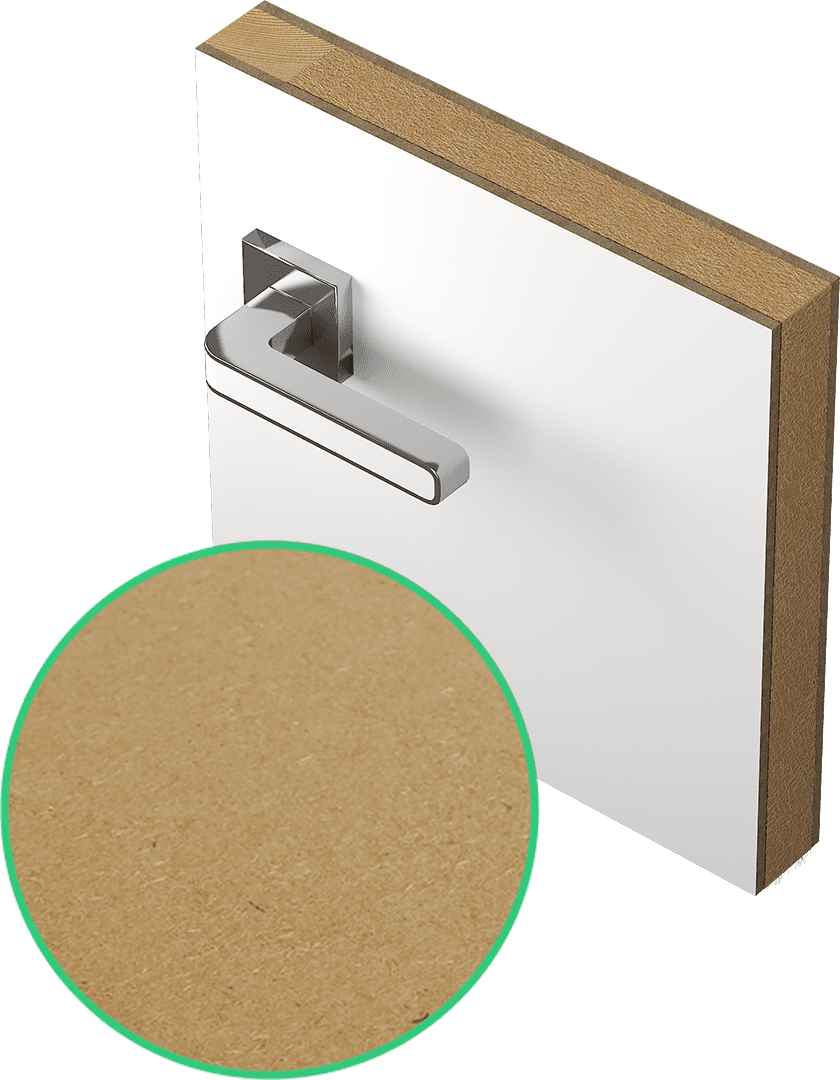

The quality solid pine frame is the basis of a strong and durable construction of Belldinni doors. The width of the frame is 1 ½’’. It undergoes several drying processes in special heating cameras which keeps the wood humidity level within 8%. The frame thickness can vary from 1 9/16’’ to 1 ¾’’ depending on the door model.

Doordesignlab doors may come with 2 types of core depending on the model, which are:

- Solid core (technologically advanced, eco-friendly filling, which is a high density natural wood fiber. This type of filling provides additional durability, noise reduction and thermal insulation.)

- Honey-comb core (filling is honey comb cells, which grant additional lightness to the door, thus protecting the hinges from extra load and still retaining high noise reduction and thermal insulation qualities)

We use high quality solid pine in the production of our frames which makes them rigid and durable enough to hold a heavy 8’ solid core door slab.

Absolutely! You can use any handle with our doors. Even more, we can make custom precuts for your specific handle! Please contact our manager to know more.

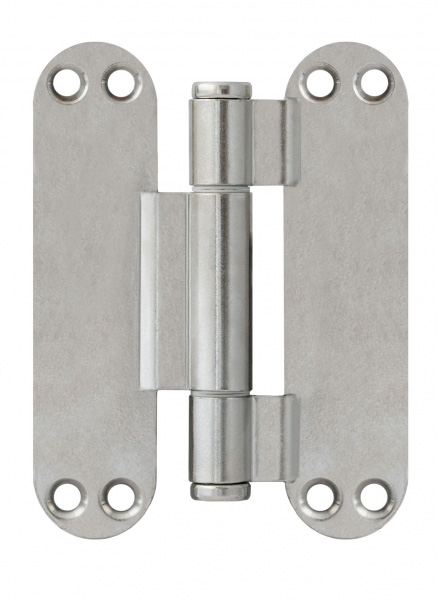

Doordesignlab doors can be fitted with several types of hinges:

1) Plain bearing hinges – quite old-fashioned and plain, as it comes from their name.

2) OTLAV 3D-adjustable concealed hinges

With the Italian made concealed

hinges, door opens smoothly and precisely up to 180°. The hinge blends seamlessly with the slab

and the frame for a markedly elegant door design solution. Thanks to the symmetric milling, the

hinge is reversible and allows choosing the door swing directly on the job site. It is 3 ways

adjustable (XYZ) which is definitely a strong competitive advantage. The decorative cover plates

conceal the adjustment screws for elegance when the door is open.

Weight capacity is 132 lbs.

per 2 hinges. Resource is 200 000 openings.

Doordesignlab door sizes are fully compliant with the US market standards. Regular sizes are:

W: 18’’,24’’,28’’,30’’,32’’,36’’

H:

80’’, 84’’, 92 ½’’, 96’’

Some models have limitations on maximum slab size.

Also, design of models may change due to bigger size. For example, “Arvika” model with 96” height will have 5 lines design instead of 4.

Please, contact our manager to know more about specific model.

Three Otlav or three plain bearing hinges.

All models available as they are listed in catalog. Painted models can be offered in different colors, but lead time will be 14-16 weeks (12 weeks with air expedited shipping) + shipping from Doordesignlab warehouse.

All Doordesignlab doors are manufactured to the highest-quality craftsmanship standards and are backed by a limited 2 year warranty against defects in workmanship and materials. Detailed warranty information is available in the following link.

Special orders are non-stock items and are non-returnable/refundable.

No returns will be accepted

unless previously authorized by Door Design Lab in writing or by email. A customer agrees and

understands that there will be restocking charge of 20% invoice price.

All returns must be in merchantable condition, in the same

packaging and/or wrapper condition as when purchased. All returned goods are subject to warehouse

inspection before credit will be issued.

Customers must provide proof of purchase for all

returned goods. No material will be accepted for return after 45 days.

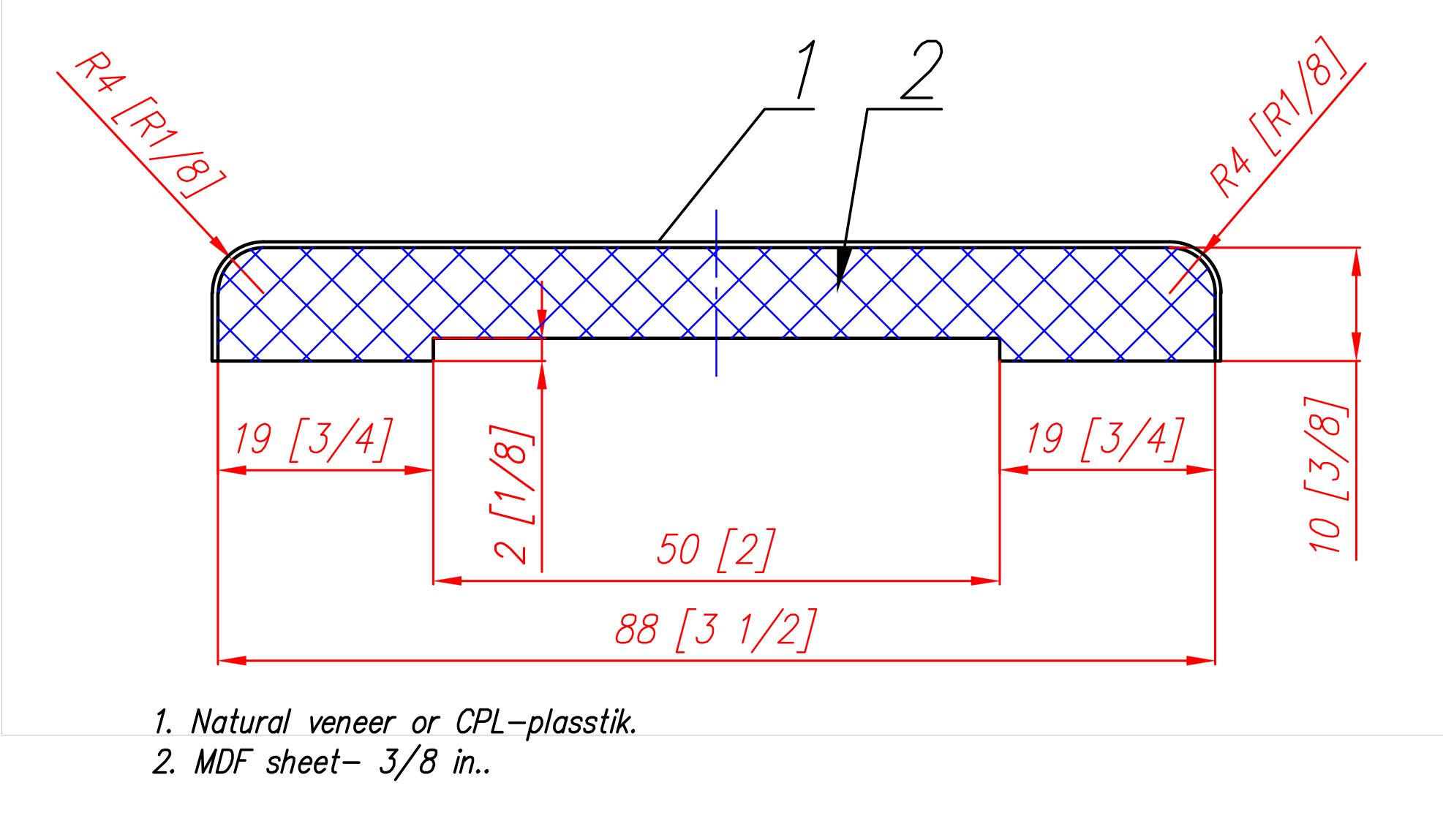

A jamb extension does precisely

what the name suggests – it's a board that fills the depth of the wall space from the inside

face of the door frame to the face of the wall and thus widens the frame. So if the wall thickness

is greater than the standard jamb width, extensions must be used.

Doordesignlab jamb extensions

are typically made of MDF and create a clean edge for the casing trim to be nailed to or inserted if

this is a telescopic L-casing.

With the help of extensions Doordesignlab frames can cover walls

4 7/8” to 6 7/8” thick.

You can purchase only slabs, we can also offer primed jambs. However, we strongly recommend that you equip the door unit with our matching jambs and casings, coated with the same finishes as the door slab.

We use high quality solid pine in the production of our jambs, which makes them rigid and durable enough to hold even a heavy 8’ solid core door slab.

Belldinni casings are made of MDF board and with the use of our telescopic L-shaped casings the thickness of the wall covered by the door frame can be extended to 5-1/2”. No other extensions needed.

Glassed Doordesignlab doors are

fitted with white or dark frosted glass of Czech production. For most glassed models, we apply

special tempered glass 1/6’’ – 1/4’’ thick. Besides high firmness, it

is also safe to use.

Should be damaged, such glass shatters into small, smooth surfaced pellets,

excluding the possibility of injury.

Door Design Lab provides a full range of options when it comes to the choice of a door configuration.

However, we strongly recommend consulting with one of our experts before placing an order, simply because the construction of our doors is different.

Once an order is processed, it

is then shipped out via LTL (for large items) or FedEx/UPS (for smaller items). LTL shipments are

curbside delivery only, unless otherwise requested. Ship times vary upon final destination, however

the average is 2-4 business days for the East Coast and 5-7 business days for the West Coast.

Dealers are also more than welcome to use their own freight company if needed.

Please contact

Doordesignlab directly for all orders outside of the continental United States.

Doordesignlab offers the

convenience of direct deliveries to our committed customers. Customer must have an agent and

facilities available to accept all deliveries of merchandise pursuant to orders placed with vendor

for shipment to customer’s office, warehouse, job sites, or any other designated location.

Customer shall take full responsibility for freight demurrage, hold-over, and similar charges

arising out of, connected with, or relating to customer’s failure to fulfill its obligations

under the terms of the clause- regardless of the origin of the shipment or the consignor.

Once a

delivery is received, the customer must inspect the contents of each package before signing the bill

of lading. All visible damages must be noted on the bill of lading, however, it is also very

important to open all received boxes and inspect the products for any concealed damage at the time

of delivery. If the driver does not allow you to inspect the freight, please note that on the bill

of lading. All damages must be reported to Doordesignlab within 48 hours of the shipment/delivery

date. Failure to comply with these rules will disqualify customers from merchandise replacement.

Please check the list of states to which we ship our products.. The delivery is handled by FedEx and UPS services. To get more accurate information about shipping costs, please follow the link from the list.

- Alabama

- Arkansas

- Colorado

- Conneticut

- Delaware

- Florida

- Georgia

- Idaho

- Illinois

- Indiana

- Iowa

- Kansas

- Kentucky

- Lousiana

- Maine

- Maryland

- Massachusetts

- Michigan

- Minnesota

- Mississippi

- Missouri

- Montana

- New Hampshire

- New Jersey

- New Mexico

- Nevada

- New York

- North Carolina

- North Dakota

- Ohio

- Oklahoma

- Oregon

- Pennsylvania

- Rhode Island

- South Carolina

- South Dakota

- Tennessee

- Texas

- Utah

- Vermont

- Virginia

- Washington

- West Virginia

- Wisconsin

- Wyoming

Belldinni solid core is our

technologically advanced insulating core with the density of 12.5 lb/ft³.

It's a modern

innovative material for thermal and acoustic insulation.

It is produced with the use of wood

and environmentally friendly components.

The composition includes conifers, polyurethane,

harmless resin and paraffin emulsion.

ADVANTAGES OF BELLDINNI SOLID CORE

- Eco-friendly material

- Provides thermal and acoustic insulation

- Ability to resist temperature changes

- Does not rot and decay

- Buy and receive your purchase right away, and pay for it over several months. This payment option allows you to split the price of your purchase into fixed payment amounts that fit your monthly budget.

- If Affirm approves your loan, you'll see your loan terms before you make your purchase.See exactly how much you owe each month, the number of payments you must make, and the total amount of interest you’ll pay over the course of the loan. There are no hidden fees.

- The application process is secure and real-time.Affirm asks you for a few pieces of information. After you provide this information, Affirm notifies you of the loan amount that you’re approved for, the interest rate, and the number of months that you have to pay off your loan -- all within seconds. For example, on a $700 purchase, you may pay $63.18 for 12 months with a 15% APR.

- You don’t need a credit card to make a purchase.Affirm lends to the merchant directly on your behalf.

- You may be eligible for Affirm financing even if you don’t have an extensive credit history.Affirm bases its loan decision not only on your credit score, but also on several other data points about you.

- Affirm reminds you by email and SMS before your upcoming payment is dueEnable Autopay to schedule automatic monthly payments on your loan.

To sign up for Affirm, you must:

- Be 18 years or older (19 years or older in Alabama or if you’re a ward of the state in Nebraska).

- Not be a resident of Iowa (IA) or West Virginia (WV).

- Provide a valid U.S. or APO/FPO/DPO home address.

- Provide a valid U.S. mobile or VoIP number and agree to receive SMS text messages. The phone account must be registered in your name.

- Provide your full name, email address, date of birth, and the last 4 digits of your social security number to help us verify your identity.

Affirm loan-application process steps:

- At checkout, choose Pay with Affirm.

- Affirm prompts you to enter a few pieces of information: Name, email, mobile phone number, date of birth, and the last four digits of your social security number. This information must be consistent and your own.

- To ensure that you’re the person making the purchase, Affirm sends a text message to your cell phone with a unique authorization code.

- Enter the authorization code into the application form. Within a few seconds, Affirm notifies you of the loan amount you’re approved for, the interest rate, and the number of months you have to pay off your loan. You have the option to pay off your loan over three, six, or twelve months. Affirm states the amount of your fixed, monthly payments and the total amount of interest you’ll pay over the course of the loan. Your rate will be 10-36% APR based on credit, and is subject to an eligibility check. Payment options through Affirm are provided by these lending partners: affirm.com/lenders. Options depend on your purchase amount, and a down payment may be required.

- To accept Affirm’s financing offer, click Confirm Loan and you’re done.

After your purchase, you’ll receive monthly email and SMS reminders about your upcoming payments. You can also set up autopay to avoid missing a payment. Your first monthly payment is due 30 days from the date that we (the merchant) processes your order.

How does Affirm approve borrowers for loans?- Affirm asks for a few pieces of personal information: Name, email address, mobile phone number, date of birth, and the last four digits of your social security number.

- Affirm verifies your identity with this information and makes an instant loan decision.

- Affirm bases its loan decision not only on your credit score, but also on several other data points. This means that you may be able to obtain financing from Affirm even if don’t have an extensive credit history.

Affirm does a “soft” credit check, which verifies the customer's identity but does not affect a customer’s credit score. Affirm's underwriting model does not use a hard credit check. There is no effect on a consumer's credit score when they apply for an Affirm loan.

Why was I denied financing by Affirm?The merchant has no information regarding a customer's financing denial. Affirm strives to offer all credit-worthy applicants financing with Affirm, but isn’t able to offer credit in every case. Affirm will send you an email with more details about its decision. Unfortunately Affirm’s decision is final.

Why was I asked to verify my identity?If Affirm has difficulty confirming your identity, you may need to provide more information. Affirm uses modern technology to confirm your identity, including verifying your address or full SSN, or requesting a photo of your ID. Affirm takes these steps in some cases to counter fraud and provide the most accurate credit decision they can.

Why was I prompted to enter my income?Affirm may sometimes need more information about your finances and your ability to repay in order to make a credit decision. Your income gives Affirm additional insight into your ability to repay.

Why was I prompted for my checking account?Affirm may sometimes need more information about your finances and your ability to repay in order to make a credit decision. If you are prompted to link your checking account and would like to proceed, please provide the login information for your online bank account. Affirm does not store your online login credentials—they are transmitted securely to your bank. If Affirm asks you to link your checking account, Affirm won’t be able to offer you credit if:

- Your bank is not listed

- You choose not to link your checking account

- You don’t use online banking

- The username and / or password you provide is incorrect

- You're unable to successfully connect your checking account

Although Affirm is continually adding support for additional banks, they aren’t able to connect to every bank at the present time. We apologize for the inconvenience. If you’re unable to connect your bank, you’ll need to complete your purchase with another payment method.

Why was I prompted for a down payment?Affirm isn’t always able to offer credit for the full amount you request. In these cases, Affirm asks you to make a down payment with a debit card for the remainder of your purchase. The down payment amount can’t be changed and must be made upon confirming your loan and before the loan offer expires.

Will I see how much interest I am paying prior to accepting my loan?Yes! Affirm works hard to be completely transparent. You’ll see the amount of interest you’ll owe on the terms page and again on the loan confirmation page. If you pay off your loan early, you’ll receive a rebate for any interest that hasn’t yet accrued.

Why can't customers outside the U.S. use Affirm?Affirm is available only to shoppers residing in the United States. Affirm hopes to expand its services to customers outside the U.S. in the future.

Making Payments and RefundsHow do I make my payments?Before each payment is due, Affirm sends you an email or SMS reminder with the installment amount that is coming due and the due date. You have the option to sign up for autopay, so you don’t risk missing a payment. Follow these steps to make a payment:

- Go to www.affirm.com/account

- Enter your mobile phone number. Affirm sends a personalized security PIN to your phone.

- Enter this security PIN into the form on the next page and click Sign in.

- After you sign in, a list of your loans appears, with payments that are coming due. Click the loan payment you would like to make.

- Make a payment using a debit card or ACH bank transfer.

A refund posts to your Affirm account if we process your refund request. If you have already made loan payments or a down payment, Affirm issues a refund credit to the bank account or debit card that you used to make the payments.

How long does it take to get my money back in the event of a return?A refund credit appears in your account within three to ten business days, depending on your bank’s processing time.

Can I amend my order after my purchase has been processed? Can I be approved for a higher loan amount if my purchase amount increases?You cannot edit your order after you have confirmed your loan. If you want to add items to your purchase, apply for another loan with Affirm or use a different payment method.

Am I able to obtain a refund after my purchase?Refunds can be processed up to 365 days from the date your order is placed.